EPS adapts the project CPM scheduling methodology to scheduling of production and other tasks in underground and open pit mines. For example EPS is aware to deal correctly with mining specifics such as product grade, stockpiles and material flows.

EPS integrates seamlessly with the design and planning tools from our VARs and allow for bi-directional passing of information. For example mining blocks / stopes / development can be prepared in the design tool and then be transferred to EPS to be refined and scheduled. Likewise schedule results can be sent back to a visualization tool where schedules can be graphically animated.

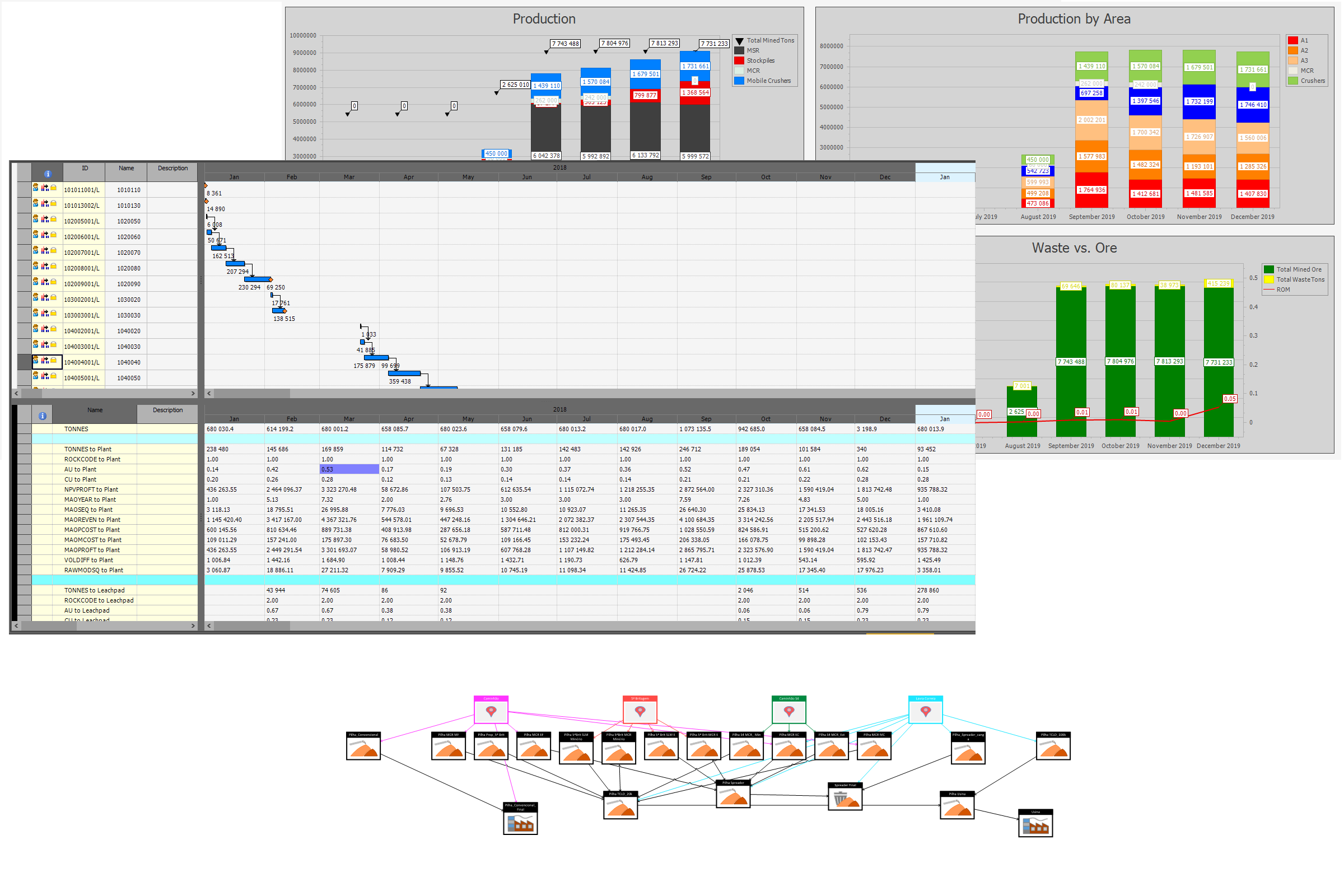

The very customizable multi-tab user interface allows users to modify the schedule in one Gantt chart view while simultaneously considering resource loading in another tab with a Resource Gantt view and keeping an eye on overall mining KPI’s using a dashboard view in another tab.

The system allows for detailed resource modeling with a powerful resource and target levelling algorithm. If more advanced scheduling / blending is necessary, the optional EPSolver add-on can be used.

The material flow chart can be used to visualize flow of materials between areas in the mine and various stockpiles, plants and waste dumps.

Full customizable reports can be created using the crosstab / histogram view, pivot tables and dashboards.

It is possible to use EPS in all phases of mining – from LOM plans all the way down to very short term scheduling of detail tasks.

Contact one of our VARs:

| Datamine Software |

| MineRP |

| Contact us |